(12) United States Patent (10) Patent No.: US 6,261,710 B1

|

|

|

- Andrew Shields

- 5 years ago

- Views:

Transcription

1 USOO OB1 (12) United States Patent (10) Patent No.: Marianowski (45) Date of Patent: Jul. 17, 2001 (54) SHEET METAL BIPOLAR PLATE DESIGN 5,578,388 11/1996 Faita et al.. FOR POLYMER ELECTROLYTE 5,606,641 2/1997 Bucaille. MEMBRANE FUEL CELLS 5,616,431 4/1997 Kusunoki et al.. 5,776,624 7/1998 Neutzler. 5,922,485 7/1999 Enami /26 (75) Inventor: total i. Marianowski, Mount 6,066,409 * 5/2000 Ronne et al /39 rospect, IL (US) 6,080,502 6/2000 Nolscher et al /34 (73) Assignee: Institute of Gas Technology, Des FOREIGN PATENT DOCUMENTS Plaines, IL (US) /1999 (GB). (*) Notice: Subject to any disclaimer, the term of this 1O /1998 (JP). patent is extended or adjusted under , 8% U.S.C. 154(b) by 0 days f /1995 (WO). a -- y ys. 97/ /1997 (WO). 98/ /1998 (WO). 22) Filled:... 25, 1998 (22) File Nov. 25, Merriam-Webster's Collegiate Dictionary, 10th ed., p (51) Int. Cl."... H01M 2700; H01M 2/18 No Month, (52) U.S. Cl /34; 429/26; 429/35; sk - 429/38; 429/39 cited by examiner (58) Field of Search /26, 34, 35, Primary Examiner-Gabrielle Brouillette 429/38, 39 Assistant Examiner Tracy Dove (74) Attorney, Agent, or Firm-Pauley Petersen Kinne & (56) References Cited Fejer U.S. PATENT DOCUMENTS (57) ABSTRACT 4,175,165 11/1979 Adlhart. A separator plate for a polymer electrolyte membrane fuel 4,678,724 7/1987 McElroy. cell Stack constructed of at least two coextensive sheet metal elements shaped to promote the distribution of reactant gases to the electrodes of the fuel cell units of the fuel cell Stack. The coextensive sheet metal elements are nestled 4,963,442 10/1990 Marianowski et al.. 4,977,041 12/1990 Shiozawa et al.. 5,077,148 12/1991 Schora et al.. 5, /1993 Marianowski et al.. 5, /1994 Marianowski et al.. together and form a coolant flow Space therebetween. 5,470,679 5,482,792 11/1995 Lund et al.. 1/1996 Faita et al.. 19 Claims, 4 Drawing Sheets COOING FLUID

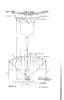

2 U.S. Patent Jul. 17, 2001 Sheet 1 of 4 COOING FLUID FIG.1

3 U.S. Patent Jul. 17, 2001 Sheet 2 of 4

4 U.S. Patent Jul. 17, 2001 Sheet 3 of 4 s

5 U.S. Patent Jul. 17, 2001 Sheet 4 of 4 s

6 1 SHEET METAL BIPOLAR PLATE DESIGN FOR POLYMER ELECTROLYTE MEMBRANE FUEL CELLS BACKGROUND OF THE INVENTION 1. Field of the Invention This invention relates to a bipolar separator plate for use in polymer electrolyte membrane (PEM) fuel cells. More particularly, this invention relates to a liquid cooled, bipolar sheet metal Separator plate for use in polymer electrolyte membrane fuel cells. Although the concept of this invention may be applied to bipolar Separator plates for a variety of fuel cell designs, it is particularly Suitable for use in polymer electrolyte membrane fuel cell stacks in which the fuel and oxidant are provided to each of the fuel cell units comprising the fuel cell Stack through internal manifolds. 2. Description of Prior Art There are a number of fuel cell systems currently in existence and/or under development which have been designed and are proposed for use in a variety of applica tions including power generation, automobiles, and other applications where environmental pollution is to be avoided. These include molten carbonate fuel cells, Solid oxide fuel cells, phosphoric acid fuel cells, and polymer electrolyte membrane fuel cells. One issue associated with Successful operation of each of these fuel cell types is the control of fuel cell temperature and the removal of products generated by the electrochemical reactions from within the fuel cell. Polymer electrolyte membrane fuel cells are particularly advantageous because they are capable of providing poten tially high energy output while possessing both low weight and low volume. Polymer electrolyte membrane fuel cells are well known in the art. Each Such fuel cell comprises a membrane-electrode-assembly' comprising a thin, proton conductive, polymer membrane-electrolyte having an anode electrode film formed on one face thereof and a cathode electrode film formed on the opposite face thereof. In general, Such membrane-electrolytes are made from ion exchange resins, and typically comprise a perflourinated sulfonic acid polymer such as NAFIONTM available from E.I. DuPont DeNemours & Co. The anode and cathode films typically comprise finely divided carbon particles, very finely divided catalytic particles Supported on the internal and external Surfaces of the carbon particles, and proton conductive material intermingled with the catalytic and carbon particles, or catalytic particles dispersed throughout a polytetrafluoroethylene (PTFE) binder. The membrane-electrode-assembly for each fuel cell is Sandwiched between a pair of electrically conductive ele ments which Serve as current collectors for the anode/ cathode and frequently contain an array of grooves in the faces thereof for distributing the fuel cell gaseous reactants over the Surfaces of the respective anode and cathode. Commercially viable fuel cell StackS may contain up to about 600 individual fuel cells (or fuel cell units), each having a planar area up to Several Square feet. In a fuel cell Stack, a plurality of fuel cell units are Stacked together in electrical Series, Separated between the anode electrode of one fuel cell unit and the cathode electrode of an adjacent fuel cell unit by an impermeable, electrically conductive, bipolar separator plate which provides reactant gas distri bution on both external faces thereof, which conducts elec trical current between the anode of one cell and the cathode of the adjacent cell in the Stack, and which, in most cases, includes the internal passages therein which are defined by internal heat exchange faces and through which coolant flows to remove heat from the Stack. Such a bipolar Sepa rator plate is taught, for example, by U.S. Pat. No. 5,776, 624. In Such fuel cell stacks, the fuel is introduced between one face of the Separator plate and the anode side of the electrolyte and oxidant is introduced between the other face of the Separator plate and the cathode Side of a Second electrolyte. Cell Stacks containing 600 cells can be up to Several feet tall, presenting Serious problems with respect to maintaining cell integrity during heat-up and operation of the fuel cell Stack. Due to thermal gradients between the cell assembly and cell operating conditions, differential thermal expansions, and the necessary Strength of materials required for the various components, close tolerances and very dif ficult engineering problems are presented. In this regard, cell temperature control is highly significant and, if it is not accomplished with a minimum temperature gradient, uni form current density will not be maintainable, and degrada tion of the cell will occur. In addition to temperature considerations, fuel cell Stack integrity is also a function of the physical dimensions of the stack. The larger the fuel cell stack, the more difficult it becomes to maintain Stack integrity and operation. Accordingly, in addition to temperature control, for a given electrical output which is a function of the number of fuel cell units comprising the fuel cell Stack, it is desirable that the fuel cell Stack dimensions, in particular, the fuel cell Stack height be as Small as possible for a given electrical output. SUMMARY OF THE INVENTION Accordingly, it is one object of this invention to provide a polymer electrolyte membrane fuel cell Stack having a compact design Such that the number of fuel cell units per inch of fuel cell Stack height for a given electrical output is increased over conventional polymer electrolyte membrane fuel cell Stacks. It is another object of this invention to provide a compact, water cooled bipolar Separator plate for use in polymer electrolyte membrane fuel cell StackS. These and other objects of this invention are achieved by a polymer electrolyte membrane fuel cell Stack comprising a plurality of polymer electrolyte membrane fuel cell units, each of which comprises a membrane-electrode-assembly comprising a thin, proton conductive, polymer membrane electrolyte having an anode electrode film on one face thereof and a cathode electrode film on an opposite face thereof, an anode current collector on Said anode electrode film Side of Said membrane-electrode-assembly and a cath ode current collector on Said cathode electrode film Side of Said membrane-electrode-assembly. Disposed between the anode electrode film Side of the membrane-electrode assem bly of one fuel cell unit and the cathode electrode film side of the membrane-electrode-assembly of an adjacent fuel cell unit is a separator plate having guide means for distributing fuel and oxidant gases to the anode electrode and the cathode electrode, respectively. The Separator plate is constructed of at least two coextensive sheet metal elements having Sub Stantially identically shaped guide means, which coexten Sive sheet metal elements are nestled together and form a coolant flow Space therebetween. In accordance with one preferred embodiment of this invention, the guide means comprise a plurality of corruga tions formed in the two sheet metal elements. In accordance with another preferred embodiment of this invention, the guide means comprise a plurality of dimples formed in the

7 3 two sheet metal elements. Although nestled together, the two coextensive sheet metal elements are maintained at a Small distance from one another, thereby forming the coolant flow Space therebetween. The distance between the nestled coex tensive sheet metal elements is maintained by Separation means Such as a plurality of nodules or bumps disposed on the face of at least one of the coextensive sheet metal elements facing another of Said coextensive sheet metal elements or other means for maintaining the Separation between the coextensive sheet metal elements while still providing good electrical conductivity between the coexten Sive sheet metal elements. BRIEF DESCRIPTION OF THE DRAWINGS These and other objects and features of this invention will be better understood from the following detailed description taken in conjunction with the drawings wherein: FIG. 1 is an exploded perspective view of a portion of a polymer electrolyte membrane fuel cell Stack including Separator plates in accordance with one embodiment of this invention; FIG. 2 is a top view of a Separator plate in accordance with one embodiment of this invention for a polymer electrolyte membrane fuel cell; FIG. 3 is a cross-sectional view of a portion of the separator plate shown in FIG. 2 in the direction of arrows III-III; FIG. 4 is a plan view of an electrode facing Side of a sheet metal element of a separator plate in accordance with one embodiment of this invention; and FIG. 5 is a plan view of a cooling fluid side of a sheet metal element of a separator plate in accordance with one embodiment of this invention. DESCRIPTION OF PREFERRED EMBODIMENTS FIG. 1 is an exploded perspective view of a portion of a polymer electrolyte membrane fuel cell stack 10 in accor dance with one embodiment of this invention. Polymer electrolyte membrane fuel cell Stack 10 comprises a plurality of polymer electrolyte membrane fuel cell units, each of which comprises a membrane-electrode-assembly (MEA) 20 comprising a thin, proton conductive, polymer membrane-electrolyte having an anode electrode film (anode) formed on one face thereof and a cathode electrode film (cathode) formed on the opposite face thereof, which membrane-electrode-assembly 20 is sandwiched between electrically conductive elements 26, 27 which serve as current collectors and gas diffusion layers for the anode and cathode. Separator plate 40 Separates adjacent polymer electrolyte membrane fuel cell units and is disposed between the anode Side of one Said polymer electrolyte membrane fuel cell unit and the cathode side of the adjacent Said polymer electrolyte membrane fuel cell unit. Separator plate 40 is formed with guide means for distribution of fuel and oxidant reactant gases to the anode and the cathode, respec tively. Such guide means may take any Suitable form but, in accordance with one preferred embodiment of this invention, comprise a plurality of corrugations 60, as shown in FIG. 2, which form channels for distribution of the reactant gases to the electrodes. In accordance with another embodiment of this invention, Said guide means comprise a plurality of dimples 61, also shown in FIG. 2. As shown in FIG. 2, Separator plate 40 may comprise a plurality of guide means, Such as a combination of corrugations and dimples In accordance with a particularly preferred embodiment of this invention, the polymer electrolyte membrane fuel cell stack of this invention is a fully internal manifolded fuel cell Stack whereby the reactant gases are provided to the elec trodes and the reaction products are withdrawn from the reaction Zones within the fuel cell Stack through internal manifolds formed by aligned perforations disposed within at least a separator plate and the polymer electrolyte mem branes. Internal manifolded fuel cells are taught by U.S. Pat. No. 4,963,442, U.S. Pat. No. 5,077,148, U.S. Pat. No. 5,227,256, and U.S. Pat. No. 5,342,706, the teachings of which are all incorporated herein by reference. It will, however, be apparent to those skilled in the art that other fuel cell configurations, including externally manifolded fuel cell Stacks, are Suitable for use with the Separator plate of this invention. As shown in FIG. 1, a fuel cell unit of a polymer electrolyte membrane fuel cell Stack in accordance with one embodiment of this invention comprises Separator plates 40, membrane electrode assembly 20 comprising a thin, proton conductive, polymer membrane-electrolyte having an anode electrode film formed on one face thereof and a cathode electrode film formed on the opposite face thereof, anode current collector 26, and cathode current collector 27. Sepa rator plates 40, membrane-electrode-assembly 20, and cur rent collectors 26, 27 extend to the edge region of the cell and form seals at both faces of separator plates 40 between membrane-electrode-assembly 20 and/or current collectors 26, 27 around the entire periphery of the cell in peripheral seal areas 43. Peripheral seal structures 43 extend upwardly and downwardly from the general plane of Separator plate 40 to provide contact with the periphery of current collectors 26, 27 and/or membrane-electrode-assembly 20. Separator plates 40, membrane-electrode-assembly 20, and current collectors 26, 27 are each penetrated by corresponding fuel manifold holes 24, one for Supply and one for removal, and oxidant manifold holes 25, one for supply and one for removal. While the manifold holes shown in FIG. 1 are a preferred triangular shape providing easily formed Straight thin sheet manifold Seal areas, the manifold holes may be round, rectangular, or any other desired shape. The manifold holes shown in FIG. 1 are single openings, but partitions may be used in the Single openings as desired to direct gas flow across the cell reactant chambers. Fuel manifold Seal areas 45 and oxidant manifold Seal areas 46 extend both upwardly and downwardly from the general plane of Sepa rator plate 40 to provide contact with the current collectors 26, 27 and/or membrane-electrode-assembly 20 to form Seals between the membrane-electrode-assembly and the adjacent current collectors 26, 27. Oxidant manifold holes 25 are sealed by oxidant manifold seals 46 providing oxidant flow only to and from the cathode chamber adjacent the upper face of Separator plate 40 by oxidant Supply openings 48 and oxidant exhaust openings 48' and preventing gas flow to or from the anode chamber while fuel manifold holes 24 are sealed by fuel manifold seals 45 providing fuel flow only to and from the anode chamber adjacent the lower face of separator plate 40 by fuel Supply openings 47 and fuel exhaust openings 47" and preventing gas flow to or from the cathode chamber. Although shown as Straight pressed sheet metal Structures, manifold seals 45, 46 can be any desired shape or structure to prevent gas flow. Manifold seals 45, 46 form a double seal between fuel manifold hole 24 and oxidant manifold hole 25. AS previously Stated, a Substantial problem which must be addressed during the operation of polymer electrolyte mem

8 S brane fuel cell Stacks is the control of fuel cell temperatures generated by the electrochemical reactions of the fuel and oxidant reactants within the fuel cell units comprising the fuel cell Stack. This objective is achieved by a separator plate 40 in accordance with this invention comprising at least two coextensive sheet metal elements 30, 31, as shown in FIGS. 1 and 3, having Substantially identically shaped guide means, for example, corrugations 60a and 60b, which at least two coextensive sheet metal elements 30, 31 are nestled together and form a coolant flow space 32 therebetween. The coolant flow Space 32 is formed by maintaining the at least two coextensive nestled sheet metal elements 30, 31 at a distance from each other. Such distance is maintained in accordance with one particularly preferred embodiment of this invention by the presence of a plurality of bumps or nodules 33 on a sheet metal element facing face of at least one of the two coextensive nestled sheet metal elements 30, 31. It will be apparent to those skilled in the art that such bumps or nodules 33 may be disposed on the sheet metal element facing face of both of the coextensive nestled sheet metal elements 30, 31. In addition, it will be apparent to those skilled in the art that welding or brazing at these points may be desirable to promote better electrical conductivity. It will also be apparent to those skilled in the art that a Separator plate 40 comprising more than two coextensive nestled sheet metal elements whereby a coolant flow Space is maintained between each of the individual sheet metal elements may also be employed in a polymer electrolyte membrane fuel cell Stack in accordance with this invention. In order to provide coolant to coolant flow Space 32, Separator plate 40, membrane-electrode-assembly 20, and current collectors 26, 27 are provided with coolant fluid manifold openings 50, 50', for input and output of cooling fluid. Coolant fluid manifold Sealant areas 51 extend on both faces from the general plane of Separator plate 40 to provide contact for forming Seals between Separator plate 40 and membrane-electrode-assembly 20 and/or current collectors 26, 27 and define a coolant fluid manifold. Coolant fluid manifold openings 50, 50' are the same diameter in each of the cell components to allow the flat Surface of the coolant fluid manifold Seal areas 51 to force contact between membrane-electrode-assembly 20 and anode current collec tor 26 on one Side and between membrane-electrode assembly 20 and cathode current collector 27 on the other Side to form a Seal Surrounding the coolant fluid manifold. The side walls of the extended coolant fluid manifold Seal areas 51 are Solid in Separator plates 40 and, thus, preclude entry of cooling fluid into either the anode chamber or the cathode chamber. Coolant fluid openings 53 in the side walls of the extended coolant fluid manifold seal areas 51 provide for communication between coolant fluid manifold openings 50, 50' and coolant flow space 32. Another object of this invention is to provide a fuel cell Stack having a higher power density than conventional fuel cell Stacks. By nestling the sheet metal elements comprising the bipolar Separator plate in accordance with this invention, it is possible to provide a fuel cell stack made up of fuel cell units per inch of fuel cell Stack. That is, a one foot high fuel cell Stack of polymer electrolyte membrane fuel cells in accordance with this invention could contain up to 360 fuel cell units. If each fuel cell unit has an area of about one square foot, then a power density of 86,400 watts 1 ft, or 3,050 watts per liter is obtained (360 fuel cell unitsx400 amps per foot Squaredx0.6 V/cell). Separator plate 40, as previously Stated, comprises at least two coextensive sheet metal elements 30, 31 which are nestled together and form a coolant flow Space 32 therebe tween. The distance between coextensive sheet metal ele ments 30, 31 is Such as to maintain as low a coolant fluid pressure differential through the coolant flow Space 32 as possible. In accordance with a preferred embodiment of this invention, the distance between the coextensive sheet metal elements 30, 31 is in the range of about inches to about inches. Coextensive sheet metal elements 30, 31 are preferably constructed of nickel, Stainless Steel, high alloy Steel, titanium and/or metals coated to prevent corrosion, having a thickness in the range of about to about inches. Because of the thinness of the sheet metal elements 30, 31, bumps or nodules 33 form maintaining sheet metal elements 30, 31 at a distance from one another are preferably embossed into the sheet metal elements 30, 31. It will be apparent to those skilled in the art, however, that other means for maintaining a distance between sheet metal elements 30, 31 including resistance welding of at least Some of the bumps or nodules may also be employed. Resistance welding at least Some of the bumps or nodules, in addition to enabling a distance to be maintained between sheet elements 30, 31, also provides for low contact resis tance between sheet metal elements 30, 31 which, in turn, inhibits the creation of high electrical resistance across the separator plate 40. FIG. 4 shows a plan view of an electrode facing face of a sheet metal element 70 of a separator plate in accordance with one embodiment of this invention. The center portion of sheet metal element 70 is the active area and comprises guide means in the form of corrugation 60 for distributing gaseous reactants to one of the electrodes of a membrane electrode assembly, which guide means are typically pressed into said sheet metal element 70. The areas of sheet metal element 70 Surrounding the active area, which areas provide Sealing between the sheet metal elements 70 comprising the Separator plate of this invention and between the Separator plate and adjacent elements of a fuel cell Stack, are generally flat. To assist in the distribution of reactant gases to the electrodes, a portion of the flat areas corresponding gener ally to the dimpled Section of the Separator plate shown in FIG. 2 are provided with reactant gas guide means for distributing the reactant gases to the active area of the separator plate. Unlike the dimples 61 shown in FIG. 2 which are normally formed by pressing of the sheet metal element, the guide means shown in FIG. 4, which are also in the form of dimples 61a are applied to the flat portion of the Sheet metal element 70 by a print Screening process known to those skilled in the art. It will also be apparent to those skilled in the art that other forms of print screened guide means, Such as rails, may also be employed and are deemed to be within the scope of this invention. FIG. 5 is a plan view of the cooling fluid facing side of sheet metal element 70, which comprises corrugated and flat Sections corresponding to the corrugated and flat Sections on the electrode facing side of sheet metal element 70. As shown in FIGS. 4 and 5, the flat portions of sheet metal element 70 comprise the periphery of sheet metal element 70 as well as Surround the gas manifold openings 24, 25 and the cooling fluid manifold openings 50, 50'. As shown in FIG. 3, Sealing between sheet metal elements 30, 31 is provided by a gasket material 34 which extends around the periphery of the Separator plate as well as around the manifold openings formed by the sheet metal elements 30, 31. Gasket material 34 may be any Sealing material Suitable for per forming the function. In accordance with one preferred embodiment of this invention, the gasket is formed by Screen printing directly onto the flat portions of sheet metal element 70.

9 7 To distribute the cooling fluid entering cooling fluid Space 32 through cooling fluid opening 50, the flat portions of sheet metal element 70 on the cooling fluid facing side thereof are provided with cooling fluid guide means which are also Screen printed thereon. Said cooling fluid guide means are preferably in the form of dimples or rails 66. In addition to providing means for distributing the cooling fluid, the cooling fluid guide means, as well as the gasket 34, are Suitable for maintaining a separation between the sheet metal elements. While in the foregoing specification this invention has been described in relation to certain preferred embodiments thereof, and many details have been Set forth for purpose of illustration, it will be apparent to those skilled in the art that the invention is Susceptible to additional embodiments and that certain of the details described herein can be varied considerably without departing from the basic principles of the invention. I claim: 1. In a polymer electrolyte membrane fuel cell Stack comprising a plurality of polymer electrolyte membrane fuel cell units, each Said fuel cell unit having a membrane electrode-assembly comprising a proton conductive, poly mer electrolyte membrane with an anode electrode film on one face and a cathode electrode film on an opposite face, an anode current collector on Said anode electrode film Side of Said membrane-electrode-assembly and a cathode current collector on Said cathode film Side of Said membrane electrode-assembly, and a separator plate disposed between Said anode electrode film Side of Said membrane-electrode assembly of one said fuel cell unit and Said cathode electrode film Side of Said membrane-electrode-assembly of an adja cent said fuel cell unit having guide means for distributing fuel and OXidant gases to Said anode electrode film Side and Said cathode electrode film Side, respectively, the improve ment comprising: Said Separator plate constructed of at least two coexten Sive sheet metal elements having Substantially con forming non-linear shapes, Said at least two coexten Sive sheet metal elements separated by a Substantially uniform distance over their entire Surfaces and forming a coolant flow Space therebetween. 2. A polymer electrolyte membrane fuel cell Stack in accordance with claim 1, wherein Said guide means com prises a plurality of corrugations formed in Said at least two sheet metal elements. 3. A polymer electrolyte membrane fuel cell Stack in accordance with claim 1, wherein Said guide means com prise a plurality of dimples formed in Said at least two sheet metal elements. 4. A polymer electrolyte membrane fuel cell Stack in accordance with claim 1, wherein Said at least two coexten Sive sheet metal elements are maintained at Said Substan tially uniform distance from each other by a plurality of bumps embossed onto a sheet metal element facing face of at least one of Said at least two coextensive sheet metal elements. 5. A polymer electrolyte membrane fuel cell stack in accordance with claim 1, wherein Said fuel cell Stack com prises in a range of about 15 to 30 polymer electrolyte membrane fuel cell units per inch of fuel cell Stack height. 6. A polymer electrolyte membrane fuel cell Stack in accordance with claim 1, wherein Said Substantially uniform distance between Said at least two sheet metal elements is in a range of about inches to about inches. 7. A polymer electrolyte membrane fuel cell stack in accordance with claim 1, wherein Said at least two sheet metal elements are constructed of a material Selected from the group consisting of nickel, Stainless Steel, high alloy Steel, titanium, and metals coated to prevent corrosion. 8. A polymer electrolyte membrane fuel cell stack in accordance with claim 1 further comprising a plurality of internal manifolds for Supplying Said fuel and oxidant gases to each of Said polymer electrolyte membrane fuel cells and for removal of exhaust gases therefrom. 9. A polymer electrolyte membrane fuel cell stack in accordance with claim 2, wherein Said at least two coexten Sive sheet metal elements are maintained at Said Substan tially uniform distance from each other by a plurality bumps embossed onto a plurality of peaks of Said corrugations on a sheet metal element facing face of at least one of Said at least two coextensive sheet metal elements. 10. A polymer electrolyte membrane fuel cell stack in accordance with claim 1, wherein Said at least two coexten Sive sheet metal elements are maintained at Said Substan tially uniform distance from each other by a gasket material disposed around a periphery of Said coextensive sheet metal elements between Said coextensive sheet metal elements. 11. A polymer electrolyte membrane fuel cell Stack in accordance with claim 1, wherein Said Separator plate com prises a centrally disposed active region and Said coexten Sive sheet metal elements comprising Said Separator plate are Substantially flat Surrounding Said centrally disposed active region. 12. A polymer electrolyte membrane fuel cell Stack in accordance with claim 11, wherein Said flat portions of Said coextensive sheet elements comprise Said guide means for distributing fuel and oxidant gases into Said centrally dis posed active region to Said anode electrode film Side and Said cathode electrode film Side, respectively, said guide means comprising at least one of rails and dimples Screen printed onto said flat portions. 13. A polymer electrolyte membrane fuel cell stack in accordance with claim 11, wherein Said flat portions of Said coextensive sheet metal elements comprise cooling fluid guide means on Said facing faces of Said coextensive sheet metal elements. 14. A polymer electrolyte membrane fuel cell Stack in accordance with claim 13, wherein Said cooling fluid guide means are one of rails and dimples Screen printed onto Said flat portions. 15. In a polymer electrolyte membrane fuel cell stack comprising a plurality of polymer electrolyte membrane fuel cell units, each Said fuel cell unit having a membrane electrode-assembly comprising a proton conducting, poly mer electrolyte membrane with an anode electrode film on one face and a cathode electrode film on an opposite face, an anode current collector on Said anode electrode film Side of Said membrane-electrode-assembly and a cathode current collector on Said cathode film Side of Said membrane electrode-assembly, and a separator plate disposed between Said anode electrode film Side of Said membrane-electrode assembly of one said fuel cell unit and Said cathode electrode film Side of Said membrane-electrode-assembly of an adja cent Said fuel cell unit having guide means for distributing fuel and OXidant gases to Said anode electrode film Side and Said cathode electrode film Side and forming an anode chamber between the anode electrode film facing face of Said Separator plate and Said anode electrode film and forming a cathode chamber between the opposite cathode electrode film facing face of Said Separator plate and the cathode electrode film of an adjacent Said fuel cell unit, Said anode chamber in gas communication with a fuel gas Supply and outlet and Said cathode chamber in gas communication with an oxidant gas Supply and outlet, the improvement comprising:

10 Said Separator plate constructed of at least two coexten Sive sheet metal elements having Substantially con forming non-linear shapes, Said at least two coexten Sive sheet metal elements separated by a Substantially uniform distance over their entire Surfaces and forming a coolant flow Space therebetween; Said Separator plates having a flattened peripheral Seal Structure extending to contact one of Said membrane electrode-assemblies and Said current collectors on each face of Said Separator plates completely around Said anode chamber and Said cathode chamber, respectively, forming a peripheral Seal under cell oper ating conditions, Said membrane-electrode-assemblies and Said Separator plates each having a plurality of aligned perforations, Said perforations in Said Separator plates being Sur rounded on Said anode electrode film facing face and Said cathode electrode film facing Side by a flattened manifold Seal Structure extending to contact one of Said membrane-electrode-assemblies and Said current col lectors on Said anode electrode film facing Sides and Said cathode electrode film facing Sides of Said Sepa rator plates, forming a manifold Seal under cell oper ating conditions to form a plurality of fuel gas and oxidant gas manifolds extending through Said cell Stack; fuel conduits through said flattened manifold Seal Struc ture providing fuel gas communication between Said fuel gas manifolds and Said anode chambers on Said anode electrode film facing Side of Said Separator plates, thereby providing fully internal manifolding of fuel to and from each said fuel cell unit in said fuel cell Stack, and Oxidant conduits through said flattened manifold Seal Structure providing oxidant gas communication between Said oxidant gas manifolds and Said cathode chambers on Said cathode electrode film facing Side of Said Separator plates, thereby providing fully internal manifolding of oxidant to and from each Said fuel cell unit in Said fuel cell Stack. 16. A polymer electrolyte membrane fuel cell stack in accordance with claim 15, wherein Said Separator plates and Said membrane-electrode-assemblies form a plurality of aligned coolant fluid openings, Said openings in Said Sepa rator plates being Surrounded on Said anode electrode film facing face and Said cathode electrode film facing Side by a flattened coolant fluid manifold Seal Structure extending to contact one of Said membrane-electrode-assemblies and Said current collectors on Said anode electrode film facing sides and Said cathode electrode film facing Sides of Said Separator plates, forming a coolant fluid manifold Seal under cell operating conditions to form a plurality of coolant fluid manifolds extending through Said cell Stack. 17. A polymer electrolyte membrane fuel cell stack in accordance with claim 15, wherein Said at least two coex tensive sheet metal elements are maintained at Said Substan tially uniform distance from each other by a plurality bumps embossed onto a sheet metal element facing face of at least one of Said at least two coextensive sheet metal elements. 18. A polymer electrolyte membrane fuel cell stack in accordance with claim 15, wherein Said Substantially uni form distance between Said at least two sheet metal elements is in a range of about inches to about inches. 19. A polymer electrolyte membrane fuel cell stack in accordance with claim 15, wherein Said at least two sheet metal elements are constructed of a material Selected from the group consisting of nickel, stainless Steel, high alloy Steel, titanium, and metals coated to prevent corrosion.

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

US 2012.0034542A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0034542 A1 Martin et al. (43) Pub. Date: (54) SEAL FOR SOLID POLYMER Related U.S. Application Data ELECTROLYTE

US 2012.0034542A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0034542 A1 Martin et al. (43) Pub. Date: (54) SEAL FOR SOLID POLYMER Related U.S. Application Data ELECTROLYTE

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

(19) United States US 2004O157111A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0157111A1 Sakamoto et al. (43) Pub. Date: (54) FUEL CELL (76) Inventors: Shigeru Sakamoto, Osaka (JP); Yasunori

(19) United States US 2004O157111A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0157111A1 Sakamoto et al. (43) Pub. Date: (54) FUEL CELL (76) Inventors: Shigeru Sakamoto, Osaka (JP); Yasunori

SSSSSSSSSSSSSSSSSSSS 22. 8a 1. United States Patent (19) Maru et al. 11 4,365,007 45) Dec. 21, 1982

United States Patent (19) Maru et al. (54) FUEL CELL WITH INTERNAL REFORMING (75) Inventors: Hansraj C. Maru, Brookfield Center; Pinakin S. Patel, Danbury, both of Conn. 73 Assignee: Energy Research Corporation,

United States Patent (19) Maru et al. (54) FUEL CELL WITH INTERNAL REFORMING (75) Inventors: Hansraj C. Maru, Brookfield Center; Pinakin S. Patel, Danbury, both of Conn. 73 Assignee: Energy Research Corporation,

? Ns 54 F2 44. al-f2. (12) Patent Application Publication (10) Pub. No.: US 2013/ A1. (19) United States. (43) Pub. Date: Aug. 8, 2013.

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0199986 A1 Miller US 2013 0199986A1 (43) Pub. Date: Aug. 8, 2013 (54) (71) (72) (73) (21) (22) (60) ON EXCHANGE EXOSKELETON

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0199986 A1 Miller US 2013 0199986A1 (43) Pub. Date: Aug. 8, 2013 (54) (71) (72) (73) (21) (22) (60) ON EXCHANGE EXOSKELETON

United States Patent (19) Kawana et al.

- United States Patent (19) Kawana et al. (54) METHANOL FUEL CELL 75) Inventors: Hidejiro Kawana; Tatsuo Horiba; Kazuo Iwamoto, all of Hitachi; Kazunori Fujita, Tohkai; Kohki Tamura, Hitachi, all of Japan

- United States Patent (19) Kawana et al. (54) METHANOL FUEL CELL 75) Inventors: Hidejiro Kawana; Tatsuo Horiba; Kazuo Iwamoto, all of Hitachi; Kazunori Fujita, Tohkai; Kohki Tamura, Hitachi, all of Japan

United States Patent (19) Sammells

United States Patent (19) Sammells (54) ELECTROCHEMICAL ZINC-OXYGEN CELL 75 Inventor: Anthony F. Sammells, Naperville, Ill. 73) Assignee: Institute of GasTechnology, Chicago, Il. 21 Appl. No.: 196,749

United States Patent (19) Sammells (54) ELECTROCHEMICAL ZINC-OXYGEN CELL 75 Inventor: Anthony F. Sammells, Naperville, Ill. 73) Assignee: Institute of GasTechnology, Chicago, Il. 21 Appl. No.: 196,749

(12) Patent Application Publication (10) Pub. No.: US 2014/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2014/0087224 A1 Kim et al. US 20140087224A1 (43) Pub. Date: Mar. 27, 2014 (54) (71) (72) (73) (21) (22) (63) (30) ELECTRODE ASSEMBLY

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2014/0087224 A1 Kim et al. US 20140087224A1 (43) Pub. Date: Mar. 27, 2014 (54) (71) (72) (73) (21) (22) (63) (30) ELECTRODE ASSEMBLY

(12) Patent Application Publication (10) Pub. No.: US 2015/ A1

(19) United States US 2015O107994A1 (12) Patent Application Publication (10) Pub. No.: US 2015/0107994 A1 CHO et al. (43) Pub. Date: Apr. 23, 2015 (54) BIOSENSOR Publication Classification (71) Applicant:

(19) United States US 2015O107994A1 (12) Patent Application Publication (10) Pub. No.: US 2015/0107994 A1 CHO et al. (43) Pub. Date: Apr. 23, 2015 (54) BIOSENSOR Publication Classification (71) Applicant:

I IIIII IIIII lll (IO) Patent No.: US 7,165,566 B2. (45) Date of Patent:

I 1111111111111111 11111 1111111111 111111111111111 IIIII IIIII lll111111111111111 US007165566B2 c12) United States Patent Beebe (IO) Patent No.: US 7,165,566 B2 (45) Date of Patent: Jan.23,2007 (54) METHOD

I 1111111111111111 11111 1111111111 111111111111111 IIIII IIIII lll111111111111111 US007165566B2 c12) United States Patent Beebe (IO) Patent No.: US 7,165,566 B2 (45) Date of Patent: Jan.23,2007 (54) METHOD

AA. *alt24& DS. (12) United States Patent US 6,607,370 B2. Aug. 19, (45) Date of Patent: (10) Patent No.: Fukamachi et al.

(12) United States Patent Fukamachi et al. USOO660737OB2 (10) Patent No.: (45) Date of Patent: US 6,607,370 B2 Aug. 19, 2003 (54) MAGNETIC PUMP (75) Inventors: Masatoshi Fukamachi, Wako (JP); Osamu Sato,

(12) United States Patent Fukamachi et al. USOO660737OB2 (10) Patent No.: (45) Date of Patent: US 6,607,370 B2 Aug. 19, 2003 (54) MAGNETIC PUMP (75) Inventors: Masatoshi Fukamachi, Wako (JP); Osamu Sato,

(12) Patent Application Publication (10) Pub. No.: US 2009/ A1

(19) United States US 20090009193A1 (12) Patent Application Publication (10) Pub. No.: US 2009/0009193 A1 Hsiung et al. (43) Pub. Date: Jan. 8, 2009 (54) MOISTURE-SENSITIVE ELEMENT WITH AN INTERDIGITAL

(19) United States US 20090009193A1 (12) Patent Application Publication (10) Pub. No.: US 2009/0009193 A1 Hsiung et al. (43) Pub. Date: Jan. 8, 2009 (54) MOISTURE-SENSITIVE ELEMENT WITH AN INTERDIGITAL

United States Patent [19]

![United States Patent [19] United States Patent [19]](/thumbs/76/73521136.jpg) United States Patent [19] Murphy 111111111111111111111111111111111111111111111111111111111111111111111111111 US005479716A [11] Patent Number: 5,479,716 [4S] Date of Patent: Jan. 2, 1996 [S4] CAPACITIVE

United States Patent [19] Murphy 111111111111111111111111111111111111111111111111111111111111111111111111111 US005479716A [11] Patent Number: 5,479,716 [4S] Date of Patent: Jan. 2, 1996 [S4] CAPACITIVE

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

(19) United States US 20070268651A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0268651 A1 TAKASHIMA et al. (43) Pub. Date: Nov. 22, 2007 (54) MONOLITHIC CERAMIC CAPACITOR May 22, 2006 (JP)...

(19) United States US 20070268651A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0268651 A1 TAKASHIMA et al. (43) Pub. Date: Nov. 22, 2007 (54) MONOLITHIC CERAMIC CAPACITOR May 22, 2006 (JP)...

(12) United States Patent

USOO7310217B2 (12) United States Patent Takashima et al. (10) Patent No.: (45) Date of Patent: US 7,310,217 B2 Dec. 18, 2007 (54) MONOLITHIC CAPACITOR AND MOUNTING STRUCTURE THEREOF (75) Inventors: Hirokazu

USOO7310217B2 (12) United States Patent Takashima et al. (10) Patent No.: (45) Date of Patent: US 7,310,217 B2 Dec. 18, 2007 (54) MONOLITHIC CAPACITOR AND MOUNTING STRUCTURE THEREOF (75) Inventors: Hirokazu

TEPZZ 95785_A_T EP A1 (19) (11) EP A1 (12) EUROPEAN PATENT APPLICATION

(19) TEPZZ 978_A_T (11) EP 2 97 81 A1 (12) EUROPEAN PATENT APPLICATION (43) Date of publication: 23.12. Bulletin /2 (21) Application number: 14172928. (1) Int Cl.: F28F 3/04 (06.01) F28F 3/08 (06.01) F28F

(19) TEPZZ 978_A_T (11) EP 2 97 81 A1 (12) EUROPEAN PATENT APPLICATION (43) Date of publication: 23.12. Bulletin /2 (21) Application number: 14172928. (1) Int Cl.: F28F 3/04 (06.01) F28F 3/08 (06.01) F28F

US 9,214,722 B2 Dec. 15, 2015

I lllll llllllll Ill lllll lllll lllll lllll lllll 111111111111111111111111111111111 US009214 722B2 c12) United States Patent Georgakopoulos et al. (IO) Patent No.: (45) Date of Patent: US 9,214,722 B2

I lllll llllllll Ill lllll lllll lllll lllll lllll 111111111111111111111111111111111 US009214 722B2 c12) United States Patent Georgakopoulos et al. (IO) Patent No.: (45) Date of Patent: US 9,214,722 B2

: Y. ti- sk 22N. Sir S. United States Patent (19) Uhri 4,687,061. Aug. 18, Patent Number: 45 Date of Patent: 4 g

i, a 5 S R 4 g 68 7 6 United States Patent (19) Uhri 8 a g. A 87 OR 11 Patent Number: 45 Date of Patent: Aug. 18, 1987 (54. STIMULATION OF EARTH FORMATIONS SURROUNDING A DEVIATED WELLBORE BYSEQUENTIAL

i, a 5 S R 4 g 68 7 6 United States Patent (19) Uhri 8 a g. A 87 OR 11 Patent Number: 45 Date of Patent: Aug. 18, 1987 (54. STIMULATION OF EARTH FORMATIONS SURROUNDING A DEVIATED WELLBORE BYSEQUENTIAL

(12) United States Patent (10) Patent No.: US 6,249,200 B1

USOO6249200B1 (12) United States Patent (10) Patent No.: US 6,249,200 B1 Stelter et al. (45) Date of Patent: *Jun. 19, 2001 (54) COMBINATION OF MAGNETS FOR 4.673,482 * 6/1987 Setoyama et al.... 204/298

USOO6249200B1 (12) United States Patent (10) Patent No.: US 6,249,200 B1 Stelter et al. (45) Date of Patent: *Jun. 19, 2001 (54) COMBINATION OF MAGNETS FOR 4.673,482 * 6/1987 Setoyama et al.... 204/298

High Efficiency Collector for Laser Plasma EUV Source.

University of Central Florida UCF Patents Patent High Efficiency Collector for Laser Plasma EUV Source. 7-11-2006 Jonathan Arenberg Northrop Grumman Corporation Find similar works at: http://stars.library.ucf.edu/patents

University of Central Florida UCF Patents Patent High Efficiency Collector for Laser Plasma EUV Source. 7-11-2006 Jonathan Arenberg Northrop Grumman Corporation Find similar works at: http://stars.library.ucf.edu/patents

Apparatus and Method for the Electrolysis of Water Employing a Sulfonated Solid Polymer Electrolyte

University of Central Florida UCF Patents Patent Apparatus and Method for the Electrolysis of Water Employing a Sulfonated Solid Polymer Electrolyte 12-21-1993 Clovis Linkous University of Central Florida

University of Central Florida UCF Patents Patent Apparatus and Method for the Electrolysis of Water Employing a Sulfonated Solid Polymer Electrolyte 12-21-1993 Clovis Linkous University of Central Florida

) USOO A. United States Patent (19) 11 Patent Number: 5,363,458 Pan et al. 45 Date of Patent: Nov. 8, 1994

) USOO5363458A United States Patent (19) 11 Patent Number: 5,363,458 Pan et al. 45 Date of Patent: Nov. 8, 1994 54 FIBER OPTIC LIGHT DIFFUSER 5,119,461 6/1992 Beyer et al.... 385/147 5,168,538 12/1992

) USOO5363458A United States Patent (19) 11 Patent Number: 5,363,458 Pan et al. 45 Date of Patent: Nov. 8, 1994 54 FIBER OPTIC LIGHT DIFFUSER 5,119,461 6/1992 Beyer et al.... 385/147 5,168,538 12/1992

''. United States Patent (19) Tsikos. 11 4,353,056 45) Oct. 5, the finger under investigation. The sensing member. 21 Appl. No.

United States Patent (19) Tsikos 54 CAPACITIVE FINGERPRINT SENSOR 75 Inventor: Constantine Tsikos, Pennsauken, N.J 73 Assignee: Siemens Corporation, Iselin, N.J. 21 Appl. No.: 156,571 22 Filed: Jun. 5,

United States Patent (19) Tsikos 54 CAPACITIVE FINGERPRINT SENSOR 75 Inventor: Constantine Tsikos, Pennsauken, N.J 73 Assignee: Siemens Corporation, Iselin, N.J. 21 Appl. No.: 156,571 22 Filed: Jun. 5,

(12) Patent Application Publication (10) Pub. No.: US 2014/ A1

(19) United States US 20140216484A1 (12) Patent Application Publication (10) Pub. No.: US 2014/0216484 A1 Liu (43) Pub. Date: Aug. 7, 2014 (54) ELECTRONIC CIGARETTE (52) U.S. Cl. CPC... A24F 47/008 (2013.01)

(19) United States US 20140216484A1 (12) Patent Application Publication (10) Pub. No.: US 2014/0216484 A1 Liu (43) Pub. Date: Aug. 7, 2014 (54) ELECTRONIC CIGARETTE (52) U.S. Cl. CPC... A24F 47/008 (2013.01)

(51) Int. Cl... D06F tank. The liquid level detector includes a first resistance

US00605O112A United States Patent (19) 11 Patent Number: Walker (45) Date of Patent: Apr. 18, 2000 54). APPARATUS AND METHOD FOR 5,798,698 8/1998 Politt et al.... 73/291 DETECTING ALIQUID LEVEL IN A SEALED

US00605O112A United States Patent (19) 11 Patent Number: Walker (45) Date of Patent: Apr. 18, 2000 54). APPARATUS AND METHOD FOR 5,798,698 8/1998 Politt et al.... 73/291 DETECTING ALIQUID LEVEL IN A SEALED

(12) Patent Application Publication (10) Pub. No.: US 2001/ A1

(19) United States US 2001 0042523A1. (12) Patent Application Publication (10) Pub. No.: US 2001/0042523 A1 Kesala (43) Pub. Date: (54) METHOD AND APPARATUS FOR FEEDING GAS PHASE REACTANT INTO A REACTION

(19) United States US 2001 0042523A1. (12) Patent Application Publication (10) Pub. No.: US 2001/0042523 A1 Kesala (43) Pub. Date: (54) METHOD AND APPARATUS FOR FEEDING GAS PHASE REACTANT INTO A REACTION

(12) United States Patent

USOO7777214B2 (12) United States Patent Shin et al. (10) Patent No.: (45) Date of Patent: US 7,777,214 B2 Aug. 17, 2010 (54) PHASE CHANGE MEMORY DEVICE WITH A NOVEL ELECTRODE (75) Inventors: Jae-Min Shin,

USOO7777214B2 (12) United States Patent Shin et al. (10) Patent No.: (45) Date of Patent: US 7,777,214 B2 Aug. 17, 2010 (54) PHASE CHANGE MEMORY DEVICE WITH A NOVEL ELECTRODE (75) Inventors: Jae-Min Shin,

Alkali Metal-Cathode Solution Battery

University of Central Florida UCF Patents Patent Alkali Metal-Cathode Solution Battery 11-11-2014 Pyoungho Choi University of Central Florida Find similar works at: http://stars.library.ucf.edu/patents

University of Central Florida UCF Patents Patent Alkali Metal-Cathode Solution Battery 11-11-2014 Pyoungho Choi University of Central Florida Find similar works at: http://stars.library.ucf.edu/patents

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

(19) United States US 20110248723A1 (12) Patent Application Publication (10) Pub. No.: US 2011/0248723 A1 YEH et al. (43) Pub. Date: Oct. 13, 2011 (54) CAPACITIVE SENSOR HAVING CALIBRATION MECHANISMAND

(19) United States US 20110248723A1 (12) Patent Application Publication (10) Pub. No.: US 2011/0248723 A1 YEH et al. (43) Pub. Date: Oct. 13, 2011 (54) CAPACITIVE SENSOR HAVING CALIBRATION MECHANISMAND

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0158290 A1 MARE-ROSE et al. US 2013 O158290A1 (43) Pub. Date: Jun. 20, 2013 (54) (71) (72) (21) (22) (60) PRODUCTION OF OXYGENATED

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0158290 A1 MARE-ROSE et al. US 2013 O158290A1 (43) Pub. Date: Jun. 20, 2013 (54) (71) (72) (21) (22) (60) PRODUCTION OF OXYGENATED

43&SS756) A. as S-AL.S /2. 7r A WINS Šs SC is U%.S. a 2 Y3 ( Aug. 1, 1967 J. C. VRANA 3,333,762 ATTORNEY JOHN C. WRANA O4.0.44,- INVEVTOR.

Aug. 1, 1967 J. C. VRANA DIFFUSER FOR CENTRIFUGAL COMPRESSOR Filed Nov. l6, l966 2. Sheets-Sheet li s A. as S-AL.S /2 7r A WINS Šs SC is U%.S. 43&SS76) - /27 Y a 2 Y3 ( C2CCCXCAVAXAS BY INVEVTOR. JOHN

Aug. 1, 1967 J. C. VRANA DIFFUSER FOR CENTRIFUGAL COMPRESSOR Filed Nov. l6, l966 2. Sheets-Sheet li s A. as S-AL.S /2 7r A WINS Šs SC is U%.S. 43&SS76) - /27 Y a 2 Y3 ( C2CCCXCAVAXAS BY INVEVTOR. JOHN

(12) United States Patent (10) Patent No.: US 7,303,925 B2. Sidewell et al. (45) Date of Patent: Dec. 4, 2007

USOO7303925B2 (12) United States Patent (10) Patent No.: US 7,303,925 B2 Sidewell et al. (45) Date of Patent: Dec. 4, 2007 (54) METHOD OF DETECTING AN ANALYTE (56) References Cited FOR LATERAL FLOW IMMUNOASSAY

USOO7303925B2 (12) United States Patent (10) Patent No.: US 7,303,925 B2 Sidewell et al. (45) Date of Patent: Dec. 4, 2007 (54) METHOD OF DETECTING AN ANALYTE (56) References Cited FOR LATERAL FLOW IMMUNOASSAY

(12) United States Patent

(12) United States Patent Young USOO6419519 B1 (10) Patent No.: (45) Date of Patent: Jul. 16, 2002 (54) (75) (73) (*) (21) (22) (51) (52) (58) (56) STRIN RELEF FOR ELECTRICL CONNECTORS Inventor: SSignee:

(12) United States Patent Young USOO6419519 B1 (10) Patent No.: (45) Date of Patent: Jul. 16, 2002 (54) (75) (73) (*) (21) (22) (51) (52) (58) (56) STRIN RELEF FOR ELECTRICL CONNECTORS Inventor: SSignee:

(12) United States Patent (10) Patent No.: US 6,412,650 B1

USOO641265OB1 (12) United States Patent (10) Patent No.: US 6,412,650 B1 Warner (45) Date of Patent: Jul. 2, 2002 (54) END CLOSURE MODULES FOR MULTI- 3,608,767 A * 9/1971 Elliot et al.... 220/4.12 CELL

USOO641265OB1 (12) United States Patent (10) Patent No.: US 6,412,650 B1 Warner (45) Date of Patent: Jul. 2, 2002 (54) END CLOSURE MODULES FOR MULTI- 3,608,767 A * 9/1971 Elliot et al.... 220/4.12 CELL

Zoë 2%lvy Arafa, BY Ace. Aig. / May 28, ,793,758. Aewe// A. Ai//lings/ey. Filed March 28, 1956 MUD AND SAND SEPARATOR FOR WELL, DRILLING

May 28, 1957 Filed March 28, 1956 Aig. / L. E. BLINGSLEY MUD AND SAND SEPARATOR FOR WELL, DRILLING 26 3 Sheets-Sheet l Aewe// A. Ai//lings/ey INVENTOR. Zoë 2%lvy Arafa, BY Ace May 28, 1957 E, BILLINGSLEY

May 28, 1957 Filed March 28, 1956 Aig. / L. E. BLINGSLEY MUD AND SAND SEPARATOR FOR WELL, DRILLING 26 3 Sheets-Sheet l Aewe// A. Ai//lings/ey INVENTOR. Zoë 2%lvy Arafa, BY Ace May 28, 1957 E, BILLINGSLEY

United States Patent (19)

United States Patent (19) Dorisio Deininger et al. 54 ELECTROCHEMICAL SENSOR FOR THE DETECTION OF HYDROGEN CYANIDE 75 Inventors: Debra J. Dorisio Deininger, Longmont, Colo.; Towner B. Scheffler, Butler,

United States Patent (19) Dorisio Deininger et al. 54 ELECTROCHEMICAL SENSOR FOR THE DETECTION OF HYDROGEN CYANIDE 75 Inventors: Debra J. Dorisio Deininger, Longmont, Colo.; Towner B. Scheffler, Butler,

(54) THERMAL INTERFACE MATERIAL WITH (56) References Cited

USOO73442B2 (12) United States Patent Huang et al. () Patent No.: (45) Date of Patent: US 7.3.442 B2 Aug. 7, 2007 (54) THERMAL INTERFACE MATERIAL WITH (56) References Cited CARBON NANOTUBES U.S. PATENT

USOO73442B2 (12) United States Patent Huang et al. () Patent No.: (45) Date of Patent: US 7.3.442 B2 Aug. 7, 2007 (54) THERMAL INTERFACE MATERIAL WITH (56) References Cited CARBON NANOTUBES U.S. PATENT

United States Patent (19)

United States Patent (19) Hughes et al. 54 (75) METHODS AND APPARATUS FOR LINEAR SCAN MAGNETRON SPUTTERING Inventors: John L. Hughes, Rodeo; Gary A. Davis, Fremont; Robert J. Kolenkow, Berkeley; Carl T.

United States Patent (19) Hughes et al. 54 (75) METHODS AND APPARATUS FOR LINEAR SCAN MAGNETRON SPUTTERING Inventors: John L. Hughes, Rodeo; Gary A. Davis, Fremont; Robert J. Kolenkow, Berkeley; Carl T.

Activity. Modeling the Fuel Cell Reaction. Overview. Advance Preparation. Background Information

4 Activity 1-2 class sessions Modeling the uel Cell Reaction 2011 Regents of the University of California Overview n order to understand the chemistry of fuel cells, students are introduced to oxidation-reduction

4 Activity 1-2 class sessions Modeling the uel Cell Reaction 2011 Regents of the University of California Overview n order to understand the chemistry of fuel cells, students are introduced to oxidation-reduction

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 2008.0035140A1 (12) Patent Application Publication (10) Pub. No.: US 2008/003514.0 A1 Placer et al. (43) Pub. Date: (54) SOLAR ROOF TILE (75) Inventors: Neil V. Placer, Frederick,

(19) United States US 2008.0035140A1 (12) Patent Application Publication (10) Pub. No.: US 2008/003514.0 A1 Placer et al. (43) Pub. Date: (54) SOLAR ROOF TILE (75) Inventors: Neil V. Placer, Frederick,

(12) United States Patent (10) Patent No.: US 7,315,677 B1

USOO731.5677B1 (12) United States Patent (10) Patent No.: US 7,315,677 B1 Li et al. (45) Date of Patent: Jan. 1, 2008 (54) DUAL DOPANT DUAL ALPHA MULTIMODE 2006/0285809 A1* 12/2006 Bickham et al.... 385,123

USOO731.5677B1 (12) United States Patent (10) Patent No.: US 7,315,677 B1 Li et al. (45) Date of Patent: Jan. 1, 2008 (54) DUAL DOPANT DUAL ALPHA MULTIMODE 2006/0285809 A1* 12/2006 Bickham et al.... 385,123

(12) Patent Application Publication (10) Pub. No.: US 2014/ A1

(19) United States US 20140057138A1 (12) Patent Application Publication (10) Pub. No.: US 2014/0057138 A1 Brett et al. (43) Pub. Date: Feb. 27, 2014 (54) FUEL CELL COMPRISING AT LEAST TWO STACKED PRINTED

(19) United States US 20140057138A1 (12) Patent Application Publication (10) Pub. No.: US 2014/0057138 A1 Brett et al. (43) Pub. Date: Feb. 27, 2014 (54) FUEL CELL COMPRISING AT LEAST TWO STACKED PRINTED

(12) United States Patent

(12) United States Patent US007191654B2 (10) Patent No.: US 7,191,654 B2 Dwyer et al. (45) Date of Patent: Mar. 20, 2007 (54) METHODS AND SYSTEMS FOR ADJUSTING (56) References Cited MAGNETIC RETURN PATH

(12) United States Patent US007191654B2 (10) Patent No.: US 7,191,654 B2 Dwyer et al. (45) Date of Patent: Mar. 20, 2007 (54) METHODS AND SYSTEMS FOR ADJUSTING (56) References Cited MAGNETIC RETURN PATH

United States Patent (19)

United States Patent (19) Rajic et al. 54 FTIR SPECTROMETER WITH SOLID-STATE DRIVE SYSTEM 75 Inventors: Slobodan Rajic, Knoxville; Roland D. Seals; Charles M. Egert, both of Oak Ridge, all of Tenn. 73

United States Patent (19) Rajic et al. 54 FTIR SPECTROMETER WITH SOLID-STATE DRIVE SYSTEM 75 Inventors: Slobodan Rajic, Knoxville; Roland D. Seals; Charles M. Egert, both of Oak Ridge, all of Tenn. 73

/1977 schroeder. only a one step exposure process.

US00569.5218A United States Patent (19) 11 Patent Number: 5,695.218 Nicosia 45 Date of Patent: Dec. 9, 1997 54 GLOW-N-THE-DARK BOOK 4,237,381 12/1980 Schroeder... 250/462 4.266,164 5/1981 Schroeder.. 315/169.1

US00569.5218A United States Patent (19) 11 Patent Number: 5,695.218 Nicosia 45 Date of Patent: Dec. 9, 1997 54 GLOW-N-THE-DARK BOOK 4,237,381 12/1980 Schroeder... 250/462 4.266,164 5/1981 Schroeder.. 315/169.1

He'? United States Patent (19) Foer. 11) Patent Number: 4,595,469 (45) Date of Patent: Jun. 17, 1986 NOOH /6. PRODUCT NaCl + H2O FEED (54)

United States Patent (19) Foer 11) Patent Number: 4,595,469 (45) Date of Patent: Jun. 17, 1986 (54) I75 (73) 21 22 63 (51) (52) 58 ELECTROLYTIC PROCESS FOR PRODUCTION OF GASEOUS HYDROGEN CHLORIDE AND AOUEOUS

United States Patent (19) Foer 11) Patent Number: 4,595,469 (45) Date of Patent: Jun. 17, 1986 (54) I75 (73) 21 22 63 (51) (52) 58 ELECTROLYTIC PROCESS FOR PRODUCTION OF GASEOUS HYDROGEN CHLORIDE AND AOUEOUS

(12) United States Patent

USOO7487686B2 (12) United States Patent Wang et al. (10) Patent No.: (45) Date of Patent: US 7487,686 B2 Feb. 10, 2009 (54) HIGH-PRECISION VORTEX FLOW METER (75) Inventors: An-Bang Wang, Taipei (TW); Ming-Hsun

USOO7487686B2 (12) United States Patent Wang et al. (10) Patent No.: (45) Date of Patent: US 7487,686 B2 Feb. 10, 2009 (54) HIGH-PRECISION VORTEX FLOW METER (75) Inventors: An-Bang Wang, Taipei (TW); Ming-Hsun

(12) Patent Application Publication (10) Pub. No.: US 2001/ A1

US 2001 OO10407A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2001/0010407 A1 Ker et al. (43) Pub. Date: (54) LOW-CAPACITANCE BONDING PAD FOR (30) Foreign Application Priority

US 2001 OO10407A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2001/0010407 A1 Ker et al. (43) Pub. Date: (54) LOW-CAPACITANCE BONDING PAD FOR (30) Foreign Application Priority

(12) Patent Application Publication (10) Pub. No.: US 2009/ A1

(19) United States US 2009.0160019A1 (12) Patent Application Publication (10) Pub. o.: US 2009/0160019 A1 Yang (43) Pub. Date: Jun. 25, 2009 (54) SEMICODUCTOR CAPACITOR Publication Classification (51)

(19) United States US 2009.0160019A1 (12) Patent Application Publication (10) Pub. o.: US 2009/0160019 A1 Yang (43) Pub. Date: Jun. 25, 2009 (54) SEMICODUCTOR CAPACITOR Publication Classification (51)

(12) Patent Application Publication (10) Pub. No.: US 2016/ A1

(19) United States US 2016O247659A1 (12) Patent Application Publication (10) Pub. No.: US 2016/0247659 A1 OH et al. (43) Pub. Date: Aug. 25, 2016 (54) ELECTROSTATIC QUADRUPOLE Publication Classification

(19) United States US 2016O247659A1 (12) Patent Application Publication (10) Pub. No.: US 2016/0247659 A1 OH et al. (43) Pub. Date: Aug. 25, 2016 (54) ELECTROSTATIC QUADRUPOLE Publication Classification

Electrochemical Deposition of Carbon Nanotubes from Organic Solutions

University of Central Florida UCF Patents Patent Electrochemical Deposition of Carbon Nanotubes from Organic Solutions 7-6-2004 Lee Chow University of Central Florida Elvira Anoshkina University of Central

University of Central Florida UCF Patents Patent Electrochemical Deposition of Carbon Nanotubes from Organic Solutions 7-6-2004 Lee Chow University of Central Florida Elvira Anoshkina University of Central

(12) United States Patent (10) Patent No.: US 8,066,860 B2

USOO80668B2 (12) United States Patent () Patent No.: Barber et al. () Date of Patent: Nov. 29, 2011 (54) ARRANGEMENT OF ION EXCHANGE WO WOOOf 44477 8, 2000 MATERAL WITHIN AN W: W292; 3: ELECTRODEONIZATION

USOO80668B2 (12) United States Patent () Patent No.: Barber et al. () Date of Patent: Nov. 29, 2011 (54) ARRANGEMENT OF ION EXCHANGE WO WOOOf 44477 8, 2000 MATERAL WITHIN AN W: W292; 3: ELECTRODEONIZATION

(ΐ2) United States Patent

US009627440B2 US009627440B2 (ΐ2) United States Patent Russo et al. (ΐο) Patent No.: (4) Date of Patent: Apr. 18, 17 (4) PHASE CHANGE MEMORY APPARATUSES (71) Applicant: Micron Technology, Inc., Boise, ID

US009627440B2 US009627440B2 (ΐ2) United States Patent Russo et al. (ΐο) Patent No.: (4) Date of Patent: Apr. 18, 17 (4) PHASE CHANGE MEMORY APPARATUSES (71) Applicant: Micron Technology, Inc., Boise, ID

(12) Patent Application Publication (10) Pub. No.: US 2014/ A1

(19) United States US 2014O124381A1 (12) Patent Application Publication (10) Pub. No.: US 2014/0124381 A1 FAN (43) Pub. Date: May 8, 2014 (54) METHOD FOR PRODUCING METHANOL (52) U.S. Cl. FROMMETHANE CPC...

(19) United States US 2014O124381A1 (12) Patent Application Publication (10) Pub. No.: US 2014/0124381 A1 FAN (43) Pub. Date: May 8, 2014 (54) METHOD FOR PRODUCING METHANOL (52) U.S. Cl. FROMMETHANE CPC...

TEPZZ 89955_A T EP A2 (19) (11) EP A2 (12) EUROPEAN PATENT APPLICATION. (51) Int Cl.: G01R 15/20 ( )

(19) TEPZZ 899_A T (11) EP 2 899 1 A2 (12) EUROPEAN PATENT APPLICATION (43) Date of publication: 29.07.201 Bulletin 201/31 (1) Int Cl.: G01R 1/20 (2006.01) (21) Application number: 111708.3 (22) Date of

(19) TEPZZ 899_A T (11) EP 2 899 1 A2 (12) EUROPEAN PATENT APPLICATION (43) Date of publication: 29.07.201 Bulletin 201/31 (1) Int Cl.: G01R 1/20 (2006.01) (21) Application number: 111708.3 (22) Date of

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004OOO7357A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0007357 A1 Gabler et al. (43) Pub. Date: Jan. 15, 2004 (54) DRILLING MECHANICS LOAD CELL (22) Filed: Jul.

US 2004OOO7357A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0007357 A1 Gabler et al. (43) Pub. Date: Jan. 15, 2004 (54) DRILLING MECHANICS LOAD CELL (22) Filed: Jul.

- o. ( 12 ) United States Patent. ( 10 ) Patent No. : US 10, 073, 092 B2. ( 45 ) Date of Patent : Sep. 11, Wang

( 12 ) United States Patent Wang TOMMUNI DI UNA US010073092B2 MULIAH DAN ( 10 ) Patent No. : US 10, 073, 092 B2 ( 45 ) Date of Patent : Sep. 11, 2018 ( 54 ) APPARATUS FOR ASSAY STRIP ( S ) WITH SPECIMEN

( 12 ) United States Patent Wang TOMMUNI DI UNA US010073092B2 MULIAH DAN ( 10 ) Patent No. : US 10, 073, 092 B2 ( 45 ) Date of Patent : Sep. 11, 2018 ( 54 ) APPARATUS FOR ASSAY STRIP ( S ) WITH SPECIMEN

United States Patent (19) Gruaz et al.

United States Patent (19) Gruaz et al. (54) DEVICE FOR LOCATING AN OBJECT SITUATED CLOSE TO A DETECTION AREA AND A TRANSPARENT KEYBOARD USING SAID DEVICE 75 Inventors: Daniel Gruaz, Montigny le Bretonneux;

United States Patent (19) Gruaz et al. (54) DEVICE FOR LOCATING AN OBJECT SITUATED CLOSE TO A DETECTION AREA AND A TRANSPARENT KEYBOARD USING SAID DEVICE 75 Inventors: Daniel Gruaz, Montigny le Bretonneux;

FLOW-THROUGH CAPACITOR ASSEMBLY FOR THE TREATMENT OF A. Field of application

FLOW-THROUGH CAPACITOR ASSEMBLY FOR THE TREATMENT OF A FLUID Field of application The present invention regards a flow-through capacitor assembly for the treatment of a fluid, according to the preamble

FLOW-THROUGH CAPACITOR ASSEMBLY FOR THE TREATMENT OF A FLUID Field of application The present invention regards a flow-through capacitor assembly for the treatment of a fluid, according to the preamble

3 N. (12) Patent Application Publication (10) Pub. No.: US 2010/ A1. (19) United States CL2+ ( (43) Pub. Date: Dec.

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2010/0314261 A1 Perry US 20100314261A1 (43) Pub. Date: Dec. 16, 2010 (54) OXYGEN-CONSUMING ZERO-GAP ELECTROLYSIS CELLS WITH POROUSASOLID

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2010/0314261 A1 Perry US 20100314261A1 (43) Pub. Date: Dec. 16, 2010 (54) OXYGEN-CONSUMING ZERO-GAP ELECTROLYSIS CELLS WITH POROUSASOLID

Sep. 2, 1993 (JP) Japan (51 int. Cl... GOR 33/02

United States Patent (19) Tomita et al. 54 METHOD AND APPARATUS FOR MEASURING AMAGNETIC FELD USNGA MAGNETIC FORCE MCROSCOPE BY MAGNETZNG A PROBE AND CORRECTING A DETECTED MAGNETIC FIELD 75) Inventors:

United States Patent (19) Tomita et al. 54 METHOD AND APPARATUS FOR MEASURING AMAGNETIC FELD USNGA MAGNETIC FORCE MCROSCOPE BY MAGNETZNG A PROBE AND CORRECTING A DETECTED MAGNETIC FIELD 75) Inventors:

(12) United States Patent

USOO743665OB2 (12) United States Patent Oguni et al. (10) Patent No.: (45) Date of Patent: US 7.436,650 B2 Oct. 14, 2008 (54) LAMINATED CERAMIC CAPACITOR (75) Inventors: Toshimi Oguni, Izumo (JP); Hiroyuki

USOO743665OB2 (12) United States Patent Oguni et al. (10) Patent No.: (45) Date of Patent: US 7.436,650 B2 Oct. 14, 2008 (54) LAMINATED CERAMIC CAPACITOR (75) Inventors: Toshimi Oguni, Izumo (JP); Hiroyuki

Paponneau (45) Date of Patent: Sep. 27, 2016

(12) United States Patent USOO9453899B2 (10) Patent No.: US 9.453,899 B2 Paponneau (45) Date of Patent: Sep. 27, 2016 (54) SYSTEM FOR EFFECTING THE (52) U.S. Cl. ROTATIONAL MOVEMENT OF A SOLAR CPC... G0IS

(12) United States Patent USOO9453899B2 (10) Patent No.: US 9.453,899 B2 Paponneau (45) Date of Patent: Sep. 27, 2016 (54) SYSTEM FOR EFFECTING THE (52) U.S. Cl. ROTATIONAL MOVEMENT OF A SOLAR CPC... G0IS

(12) Patent Application Publication (10) Pub. No.: US 2016/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0079625 A1 Shon et al. US 2016.0079625A1 (43) Pub. Date: Mar. 17, 2016 (54) FLEXBLE ELECTRODE ASSEMBLY AND ELECTROCHEMICAL

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0079625 A1 Shon et al. US 2016.0079625A1 (43) Pub. Date: Mar. 17, 2016 (54) FLEXBLE ELECTRODE ASSEMBLY AND ELECTROCHEMICAL

(12) Patent Application Publication (10) Pub. No.: US 2015/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2015/0256036A1 NAKAMURA US 20150256036A1 (43) Pub. Date: Sep. 10, 2015 (54) LAMINATED IRON CORE AND MANUFACTURING METHOD FOR LAMINATED

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2015/0256036A1 NAKAMURA US 20150256036A1 (43) Pub. Date: Sep. 10, 2015 (54) LAMINATED IRON CORE AND MANUFACTURING METHOD FOR LAMINATED

in. ION SOURCE \, N. (12) Patent Application Publication (10) Pub. No.: US 2006/ A1 (19) United States 1 N 4

(19) United States US 20060219890A1 (12) Patent Application Publication (10) Pub. No.: US 2006/0219890 A1 Yamaguchi (43) Pub. Date: Oct. 5, 2006 (54) TIME OF FLIGHT MASS SPECTROMETER (75) Inventor: Shinichi

(19) United States US 20060219890A1 (12) Patent Application Publication (10) Pub. No.: US 2006/0219890 A1 Yamaguchi (43) Pub. Date: Oct. 5, 2006 (54) TIME OF FLIGHT MASS SPECTROMETER (75) Inventor: Shinichi

(12) Patent Application Publication (10) Pub. No.: US 2016/ A1

(19) United States US 20160284659A1 (12) Patent Application Publication (10) Pub. No.: US 2016/0284659 A1 CHEN et al. (43) Pub. Date: Sep. 29, 2016 (54) SEMICONDUCTOR SUBSTRATE (52) U.S. Cl. STRUCTURE,

(19) United States US 20160284659A1 (12) Patent Application Publication (10) Pub. No.: US 2016/0284659 A1 CHEN et al. (43) Pub. Date: Sep. 29, 2016 (54) SEMICONDUCTOR SUBSTRATE (52) U.S. Cl. STRUCTURE,

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

(19) United States US 20040O83815A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0083815 A1 Lam et al. (43) Pub. Date: May 6, 2004 (54) PIPE FLAW DETECTOR (76) Inventors: Clive Chemo Lam,

(19) United States US 20040O83815A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0083815 A1 Lam et al. (43) Pub. Date: May 6, 2004 (54) PIPE FLAW DETECTOR (76) Inventors: Clive Chemo Lam,

United States Patent (19)

United States Patent (19) Black, Jr. et al. (54 75 73 21 22) 51 52) 58 (56) SELFACTIVATING FERROFLUD SEAL APPARATUS AND METHOD Inventors: Thomas J. Black, Jr., Lowell; Philip Stahl, Holliston, both of

United States Patent (19) Black, Jr. et al. (54 75 73 21 22) 51 52) 58 (56) SELFACTIVATING FERROFLUD SEAL APPARATUS AND METHOD Inventors: Thomas J. Black, Jr., Lowell; Philip Stahl, Holliston, both of

(12) Patent Application Publication (10) Pub. No.: US 2014/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2014/0011074 A1 Oda et al. US 2014001 1074A1 (43) Pub. Date: (54) (71) (72) (73) (21) (22) (63) (30) NEGATIVE ELECTRODE TERMINAL

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2014/0011074 A1 Oda et al. US 2014001 1074A1 (43) Pub. Date: (54) (71) (72) (73) (21) (22) (63) (30) NEGATIVE ELECTRODE TERMINAL

(19) Scott H. Stillinger, Los Gatos, Calif. Oddz0n Products, Campbell, Calif. 60,640 Jun. 11, 1987 Int. Cl'... A63B 37/14

United States Patent Stillinger 54 (75) (73) 21 22 51 (52) (58 (56) (19) GENERALLY SPHERICAL OBJECT WITH FLOPPY FILAMENTS TO PROMOTE SURE CAPTURE Inventor: Assignee: Appl. No.: Filed: Scott H. Stillinger,

United States Patent Stillinger 54 (75) (73) 21 22 51 (52) (58 (56) (19) GENERALLY SPHERICAL OBJECT WITH FLOPPY FILAMENTS TO PROMOTE SURE CAPTURE Inventor: Assignee: Appl. No.: Filed: Scott H. Stillinger,

(54) (75) (73) (Us) (21) (22) (63) 1, 2007, provisional application No. 60/997,142,?led

US 20120120398A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0120398 A1 Armani et al. (43) Pub. Date: May 17, 2012 (54) (75) (73) (21) (22) (63) MICRO-CAVITY GAS AND VAPOR

US 20120120398A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0120398 A1 Armani et al. (43) Pub. Date: May 17, 2012 (54) (75) (73) (21) (22) (63) MICRO-CAVITY GAS AND VAPOR

United States Patent (19)

United States Patent (19) Rodov 54 METHOD OF MANUFACTURE OF ZENER DODES (75 Inventor: Vladimir Rodov, Los Angeles, Calif. 73) Assignee: International Rectifier Corporation, Los Angeles, Calif. 21 Appl.

United States Patent (19) Rodov 54 METHOD OF MANUFACTURE OF ZENER DODES (75 Inventor: Vladimir Rodov, Los Angeles, Calif. 73) Assignee: International Rectifier Corporation, Los Angeles, Calif. 21 Appl.

56 References Cited UNITED STATES PATENTS 1965, 187 7/1934 Hartman /43 3,483,374 12/1969 Erben /4 3,486,308 12/1969 Burt...

United States Patent Hochheiser et al. 54) AR PROCESSOR (72) Inventors: Jerome S. Hochheiser; Louis Zer meno, both of Los Angeles, Calif. 73 Assignee: Hochheiser Electronics Corporation, Burband, Calif.

United States Patent Hochheiser et al. 54) AR PROCESSOR (72) Inventors: Jerome S. Hochheiser; Louis Zer meno, both of Los Angeles, Calif. 73 Assignee: Hochheiser Electronics Corporation, Burband, Calif.

United States Patent (19)

United States Patent (19) Harrigan 54 LEVITATION DEVICE 76 Inventor: Roy M. Harrigan, Bromley Mountain Rd., Manchester, Vt. O54 21 22 63 51 (52) 58 Appl. No.: 105,239 Fed: Dec. 19, 1979 Related U.S. Application

United States Patent (19) Harrigan 54 LEVITATION DEVICE 76 Inventor: Roy M. Harrigan, Bromley Mountain Rd., Manchester, Vt. O54 21 22 63 51 (52) 58 Appl. No.: 105,239 Fed: Dec. 19, 1979 Related U.S. Application

(12) United States Patent

USOO71481 B2 (12) United States Patent BaltZer () Patent No.: (45) Date of Patent: Dec. 5, 2006 (54) HEADREST FOR ALLEVIATING WHIPLASH INURY AND THE USE OF SPECIFIC POLYURETHANE FOAMIS THEREN (76) Inventor:

USOO71481 B2 (12) United States Patent BaltZer () Patent No.: (45) Date of Patent: Dec. 5, 2006 (54) HEADREST FOR ALLEVIATING WHIPLASH INURY AND THE USE OF SPECIFIC POLYURETHANE FOAMIS THEREN (76) Inventor:

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1. LEE et al. (43) Pub. Date: Jan. 3, 2013

US 2013 OOO1573A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0001573 A1 LEE et al. (43) Pub. Date: Jan. 3, 2013 (54) THIN FILM TRANSISTOR AND METHOD OF Publication Classification

US 2013 OOO1573A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0001573 A1 LEE et al. (43) Pub. Date: Jan. 3, 2013 (54) THIN FILM TRANSISTOR AND METHOD OF Publication Classification

Direct Energy Conversion: Fuel Cells

Direct Energy Conversion: Fuel Cells References and Sources: Direct Energy Conversion by Stanley W. Angrist, Allyn and Beacon, 1982. Fuel Cell Systems, Explained by James Larminie and Andrew Dicks, Wiley,

Direct Energy Conversion: Fuel Cells References and Sources: Direct Energy Conversion by Stanley W. Angrist, Allyn and Beacon, 1982. Fuel Cell Systems, Explained by James Larminie and Andrew Dicks, Wiley,

(12) United States Patent (10) Patent No.: US 7825,066 B1

US00782.5066B1 (12) United States Patent (10) Patent No.: US 7825,066 B1 Skaggs et al. (45) Date of Patent: Nov. 2, 2010 (54) RAPID FORMALDEHYDE (56) References Cited NEUTRALIZATION USING CHEMICALLY TREATED

US00782.5066B1 (12) United States Patent (10) Patent No.: US 7825,066 B1 Skaggs et al. (45) Date of Patent: Nov. 2, 2010 (54) RAPID FORMALDEHYDE (56) References Cited NEUTRALIZATION USING CHEMICALLY TREATED

NOTICE. The above identified patent application is available for licensing. Requests for information should be addressed to:

Serial Number 09/659.959 Filing Date 12 September 2000 Inventor Maria G. Medeiros Catherine L. Marsh James R. Moden Hubert G. Meunier NOTICE The above identified patent application is available for licensing.

Serial Number 09/659.959 Filing Date 12 September 2000 Inventor Maria G. Medeiros Catherine L. Marsh James R. Moden Hubert G. Meunier NOTICE The above identified patent application is available for licensing.

100-N. (12) United States Patent N 2 Q US 7,234,334 B1. Jun. 26, (45) Date of Patent: (10) Patent No.: SZZ

USOO7234,334B1 (12) United States Patent Pfabe (10) Patent No.: (45) Date of Patent: US 7,234,334 B1 Jun. 26, 2007 (54) SADDLE FOR BACKING ASSEMBLIES IN A ROLLING MILL (75) Inventor: Dennis P. Pfabe, Canton,

USOO7234,334B1 (12) United States Patent Pfabe (10) Patent No.: (45) Date of Patent: US 7,234,334 B1 Jun. 26, 2007 (54) SADDLE FOR BACKING ASSEMBLIES IN A ROLLING MILL (75) Inventor: Dennis P. Pfabe, Canton,

(12) United States Patent

US00928.1819B2 (12) United States Patent Chou et al. (10) Patent No.: (45) Date of Patent: Mar. 8, 2016 (54) SOURCE DRIVING CIRCUIT AND RESISTOR RENORMALIZATION METHOD (71) Applicant: Raydium Semiconductor

US00928.1819B2 (12) United States Patent Chou et al. (10) Patent No.: (45) Date of Patent: Mar. 8, 2016 (54) SOURCE DRIVING CIRCUIT AND RESISTOR RENORMALIZATION METHOD (71) Applicant: Raydium Semiconductor

United States Patent (19)

United States Patent (19) Jongema 54 PROCESS FOR THE PREPARATION OF SODUM CHILORIDE 75) Inventor: Pieter Jongema, Brummen, Netherlands (73) Assignee: Akzo N.V., Netherlands (21) Appl. No.: 815,090 (22)

United States Patent (19) Jongema 54 PROCESS FOR THE PREPARATION OF SODUM CHILORIDE 75) Inventor: Pieter Jongema, Brummen, Netherlands (73) Assignee: Akzo N.V., Netherlands (21) Appl. No.: 815,090 (22)

United States Patent (19) Sumikawa et al.

United States Patent (19) Sumikawa et al. 11 3,983,170 (45) Sept. 28, 1976 (54) (75) 73 22 21 52) 51 58) PROCESS FOR THE PURIFICATION OF MALIC ACID Inventors: Shozo Sumikawa, Hofu, Rikichi Maida; Yuriaki

United States Patent (19) Sumikawa et al. 11 3,983,170 (45) Sept. 28, 1976 (54) (75) 73 22 21 52) 51 58) PROCESS FOR THE PURIFICATION OF MALIC ACID Inventors: Shozo Sumikawa, Hofu, Rikichi Maida; Yuriaki

United States Patent (19) Eizenhoefer et al.

United States Patent (19) Eizenhoefer et al. (54) PIEZOELECTRICSHOCKWAVE GENERATOR 75 Inventors: Harald Eizenhoefer, Johannesberg: Ernst Marlinghaus, Germering, both 73 Assignee: 21) Appl. No.: 779,113

United States Patent (19) Eizenhoefer et al. (54) PIEZOELECTRICSHOCKWAVE GENERATOR 75 Inventors: Harald Eizenhoefer, Johannesberg: Ernst Marlinghaus, Germering, both 73 Assignee: 21) Appl. No.: 779,113

(12) United States Patent (10) Patent No.: US 6,277,278 B1

USOO6277278B1 (12) United States Patent (10) Patent No.: US 6,277,278 B1 Conrad et al. (45) Date of Patent: *Aug. 21, 2001 (54) CYCLONE SEPARATOR HAVING A 1897,144 2/1933 Prouty. WARIABLE LONGITUDINAL

USOO6277278B1 (12) United States Patent (10) Patent No.: US 6,277,278 B1 Conrad et al. (45) Date of Patent: *Aug. 21, 2001 (54) CYCLONE SEPARATOR HAVING A 1897,144 2/1933 Prouty. WARIABLE LONGITUDINAL

USOO610427OA United States Patent (19) 11 Patent Number: 6,104,270 Elias (45) Date of Patent: Aug. 15, 2000

USOO610427OA United States Patent (19) 11 Patent Number: Elias (45) Date of Patent: Aug. 15, 2000 54) LIFTER WITH ELECTROPERMANENT 4.956,625 9/1990 Cardone et al.... 335/290 MAGNETS PROVIDED WITH A SAFETY

USOO610427OA United States Patent (19) 11 Patent Number: Elias (45) Date of Patent: Aug. 15, 2000 54) LIFTER WITH ELECTROPERMANENT 4.956,625 9/1990 Cardone et al.... 335/290 MAGNETS PROVIDED WITH A SAFETY

ZZZZZZZZZZYZZZZZZZZZZZZZz6

USOO5898752A United States Patent (19) 11 Patent Number: Van Der Wal (45) Date of Patent: Apr. 27, 1999 54) X-RAY ANALYSIS APPARATUS PROVIDED Primary Examiner-Craig E. Church WITH A DOUBLE COLLIMATOR MASK

USOO5898752A United States Patent (19) 11 Patent Number: Van Der Wal (45) Date of Patent: Apr. 27, 1999 54) X-RAY ANALYSIS APPARATUS PROVIDED Primary Examiner-Craig E. Church WITH A DOUBLE COLLIMATOR MASK

(12) Patent Application Publication (10) Pub. No.: US 2014/ A1

(19) United States US 20140238873A1 (12) Patent Application Publication (10) Pub. No.: US 2014/0238873 A1 Li et al. (43) Pub. Date: Aug. 28, 2014 (54) MODIFIED BUBBLING TRANSFER METHOD (52) U.S. Cl. FOR

(19) United States US 20140238873A1 (12) Patent Application Publication (10) Pub. No.: US 2014/0238873 A1 Li et al. (43) Pub. Date: Aug. 28, 2014 (54) MODIFIED BUBBLING TRANSFER METHOD (52) U.S. Cl. FOR

(12) United States Patent

USOO9633947B2 (12) United States Patent Jacob (10) Patent No.: (45) Date of Patent: Apr. 25, 2017 (54) (71) (72) (73) (*) (21) (22) (65) (51) (52) FOLDED BALLISTC CONDUCTOR INTERCONNECT LINE Applicant:

USOO9633947B2 (12) United States Patent Jacob (10) Patent No.: (45) Date of Patent: Apr. 25, 2017 (54) (71) (72) (73) (*) (21) (22) (65) (51) (52) FOLDED BALLISTC CONDUCTOR INTERCONNECT LINE Applicant:

III M

III1 11111111111111111111111111M 1 1 ))1111111 1 (19) United States (12) Patent Application Publication (lo) Pub. No.: US 2013/0343503 Al AGACE et al. ( 4 3 ) Pub. Date: D e c. 26, 2013 (54) SNAP-IN INSERT

III1 11111111111111111111111111M 1 1 ))1111111 1 (19) United States (12) Patent Application Publication (lo) Pub. No.: US 2013/0343503 Al AGACE et al. ( 4 3 ) Pub. Date: D e c. 26, 2013 (54) SNAP-IN INSERT

United States Patent (11) 3,630,782. electrical potential of primary batteries of the type immersible. Appl. No. 865,429

United States Patent 72) 21 22 45) 54 52 51) Inventor Edwin K. Butler, deceased, late of St. Petersburg, Fa, by Adrina Neil Butler, beneficiary of the estate, 6762 7th St., South St. Petersburg, Fla. 33712